Here are some interior pictures of Kismet. I didn't want to publish these until we had the curtains under control. The bottom of the curtains wasn't held against the cabin wall until recently.

Port side. EPIRB (reachable from port entryway), Drop down tables, Cutlery roll (grey) and storage containers.

Starboard side. Battery (100AH LiFePO4) (with drinking water temporarily on top), Rubbish bin - it moves around depending on land or water operation. The Origo single burner alcohol stove is in the forward locker in its box. Note the grey hull liner. I might put more of this below the stringer as it worked out really well.

View from Starboard entryway.

More general port side view. The pillows aren't the ones we use. I leave them there for times when we haven't got the main bedding on the boat in case I'd like to have a lie down...

The bed consists of a layer of Aeromesh and a layer of 50mm "eggshell" foam. The full bedding adds a 70mm Synmat (high end inflatable camping mattress) and double sleeping bag.

Porta potti and fridge in the foreground. The fridge is a Dometic CFF45 that we ran at -8 degrees C during the Whitsundays trip.

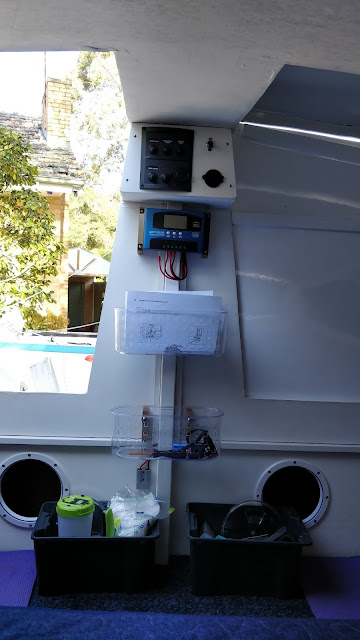

12V electric switch panel and solar controller

A couple of plastic general use containers below the solar controller.

The dark grey plastic containers on the bed are useful for general stuff as well.

Port side looking back toward the stern. In the "coffin bed" there is an under-bed storage crate with our boat shoes, the Genoa, Jib and Main sail all in purpose made bags. The Boom slides up the side of the main. The boom tent and cockpit table are in there as well. We have two 1 meter long 45cm wide 80mm thick mattresses that makes this into a nice bed area with the person halfway out of the closed in space - only carried if we have three sleeping on board. (The starboard "coffin bed" holds the dagger boards, boarding ladder (water use) and PFDs.

The curtains. They use a caravan style track and four velcro pads at the bottom to hold them against the cabin sides. The hanging strip (this one in the corner) ties them back completely off the windows.

Fire extinguisher is reachable from the starboard entryway hatch.

Note the 12V faucet that can swing out of the way when not in use. The power for the tap is only available when the cabin light switch on the switch panel is on. There is a switch on the tap as well.

You can just see part of another cabin light that points at the tables. (The main cabin light is in the centre of the roof and has a red/white setting.)

The wash up basin and personal use basins sit in behind the tables.

Table up. The basins fit exactly under the faucet. The only problem with a switched tap and no flow control is when you just want to wet a face washer or rag briefly - it's an art!

30L water tank and 12V pump mounted near the bedding. We have another two 20L water jerry cans. We only took one additional jerry can on the water in the Whitsundays and it was plenty for three people for three days. The picnic knapsack in the port front locker contains our plate, bowls and mugs.

Water tank and first aid kit. Note hull liner.

Front windows. This is where the velcro works really well. They draw off the windows toward the centre. I installed a 20mm high lip so we can leave stuff on the front window ledge. Not when road travelling though.

We haven't actually had Kismet on the water since November 2019 so the correctly held curtains haven't been enjoyed yet. Just dangling vertically was a bit of a pain on the Whitsundays trip as it stopped us being able to use the front window ledge due to objects there getting too much sun (the curtains have black out lining).